Syneffex™

Thermal Insulation Coatings

Thermal Insulation Paint

Sustainable Thermal Insulation Coatings

Nansulate™ EPX-H2O

Thermal Insulating Paint

Patented Nano-engineered Thermal Insulation in a Class of its Own.

Corrosion Proof. Chemical Resistance. Pays for Itself Fast, in Approximately 12 Months.

Keeps Saving You Money for 10 Years or More.

Our most powerful solution

Grey or white, pebbled finish

Coverage Rate per Gallon:

188 S.F. @ 1 coat (10 mils/254 microns wet film thickness)

Standard application is typically between 4-10 coats (depending upon needs)

Actual coverage rate may vary depending on surface texture. All products are sold by weight, not volume.

2-Gallon Kit

$397.90ADD TO CART

5-Gallon Kit

$994.75ADD TO CART

Clear Sustainable Thermal Insulation Coating

Nansulate™ High Heat

Thermal Insulating Paint

Patented Nano-engineered Thermal Insulation in a Class of its Own.

Corrosion Proof. Mold Resistance. Pays for Itself Fast, in Approximately 12 Months.

Keeps Saving You Money for 5-10 Years or More.

Clear, smooth finish

Coverage Rate per Gallon:

450 S.F. @ 1 coat (4 mils/100 microns wet film thickness)

Standard application is typically between 6-10 coats (depending upon needs)

Actual coverage rate may vary depending on surface texture. All products are sold by weight, not volume.

$725.00 ADD TO CART

#1 Patented Nanotech-Based Thermal Paint That Also Prevents Corrosion. Brilliant!

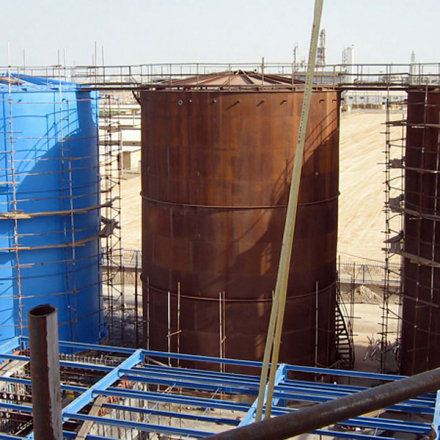

Syneffex™ thermal insulation coatings are the top choice for a wide variety of thermal insulating paint applications over equipment like pipes, pipelines, tanks, ovens, processing vessels, heat exchangers and more. Syneffex™ patented industrial thermal insulation paint solves corrosion-under-insulation (CUI) by both insulating and preventing corrosion with a single product. Our thermal paint coatings are multipurpose spray or paint applied products that are simple to deploy.

Customers report average energy savings of 20% plus with Syneffex™ Coatings!

- Save energy simply

- Meet corporate energy saving goals

- Quick-curing for fast energy reduction results

- Energy efficiency for equipment and buildings

- Reduce production costs per unit by lowering energy requirements

Syneffex™ thermal insulation coatings help organizations improve energy efficiency. They are nano-engineered patented cutting-edge thermal paint coatings that provide next generation performance beyond older, non-patented ceramic insulation products. Additionally, our products are eco-friendly and provide mold-resistant and anti-condensation properties without harmful biocides and other harsh chemicals, which is a significant plus for sustainably-minded companies.

Are you tired of dealing with insulation jackets or insulation covers that don't fit? Spray-on thermal insulating coatings by Syneffex™ fit any shape of equipment and do not require any exterior jacketing. You can spray apply this technology easily while equipment is in-service and our concentrated insulation coatings will work diligently for 5-10 years or more without degrading.

Looking for thermal coat building insulation? Click here to see our protective coatings for buildings.

Why Choose Syneffex™

Your success is our success. Let’s do it together. Today!

* Individual results can vary

✅ Easy Application

✅ Corrosion Prevention

✅ Clear Lead Encapsulation

✅ Increased Asset Lifespan

✅ Sustainable/Eco Friendly

✅ Mold and Mildew Resistant

✅ Resistant to UV and Color Fade

✅ Protects From Sea Spray and Salt Air

We have provided sustainable solutions in 60+ countries for over a decade. Find out why companies in multiple industries are choosing Syneffex™ insulation coatings over other types of insulation.

Syneffex™ Sustainable Thermal Insulation Coatings

Patented Nano-engineered Thermal Insulation in a Class of its Own. Corrosion Proof. Chemical Resistance. Pays for Itself Fast, in Approximately 12 Months. Keeps Saving You Money for 10 Years or More.

Watch Nansulate™ EPX-H2O in Action!

Syneffex™ The Brand that You Can Trust.

About Us

Syneffex™ Thermal Insulation Coatings are the top choice for a wide variety of thermal insulating paint applications over pipes, pipelines, tanks, ovens, processing vessels, heat exchangers and more.

Syneffex™ patented industrial thermal insulation paint solves corrosion-under-insulation (CUI) by both insulating and preventing corrosion with a single product. Our thermal paint coatings are multipurpose spray applied products that are simple to deploy.

How It Works

Spray-on thermal insulating coatings by Syneffex™ can be used up to 400F/204C, fit any shape of equipment and do not require any exterior jacketing.

You can spray apply this technology easily while equipment is in-service and our concentrated insulation coatings will work diligently for 10 years or more without degrading.

Syneffex™ Award Winning Thermal Insulation Coating Technology

For over a decade, Syneffex™ has served as the preferred industrial thermal barrier insulation, energy saving, surface protection and asset protection coating, meeting the needs of multiple industries around the world, including pulp and paper manufacturing, food and beverage manufacturing, U.S. military, oil and gas, textile manufacturing and many others.

Our insulation and protective coatings are designed for the harshest outdoor and offshore environments, such as those experienced by our customer Sinopec on their offshore fuel oil storage tanks, black liquor tanks in pulp and paper mills like those of Weyerhaeuser, and even in the frigid cold of Alaska where our thermal barrier insulation coatings helped insulate steam and water pipes for the U.S. Army. Our customers choose Syneffex™ industrial and building insulating coating solutions because of the superior combined energy savings, stay clean, and asset protection benefits.

Improve energy efficiency easily with our thermal barrier coatings that can be used on multiple surfaces types. Use as a stainless steel coating, steel insulation coating, copper thermal coat, galvanized coating, heat insulation coating for aluminum, and multiple other surfaces to improve energy efficiency, lower surface temperatures, reduce heat expelled into the environment from hot equipment, and stop rust and CUI.

Read about our Sustainable Case Study Blog, where we highlight a few fantastic customer projects: Sustainable Thermal Insulation Coating Projects.

Industries served include:

Insulating Coating Benefits

Perfect for Equipment Applications

Nansulate™ EPX-H2O Thermal Insulation Coating

Product Details

Nansulate™ EPX-H2O is our #1 high temperature industrial protective insulation coating for equipment. It is a super-powered thermal insulating coating that is also chemical and corrosion resistant and cures within 2 hours to 2 days. Our best in class thermal insulating coatings are proven to solve the most difficult energy efficiency, corrosion, CUI, moisture, and safe touch problems of factories and industry around the world.

Nansulate™ EPX-H2O is a complete thermal barrier insulation system for pipes, tanks, and other industrial equipment and can provide 100% insulation coverage of all odd-shaped configurations - no more expensive insulation jackets or insulated covers needed. This next generation heat insulating coating has you covered for all types of directives - energy savings, safe touch for employee safety, heat radiation reduction, and asset protection from chemicals and corrosion. Don’t leave uninsulated areas in your pipe and tank insulation system that will lead to heat and energy loss. Instead use an easy spray-on solution that can coat, protect, and insulate your entire heat process system, including valves, pipes, tanks, boilers, heat exchangers, and more. Syneffex™ thermal insulating and protective coating is a technology you can trust to perform consistently for 10 years or more.

Nansulate™ EPX-H2O Thermal Insulation and Protective Coating

Nansulate™ EPX-H2O is a powerful nano-engineered 2-part water based reactive prepolymer that provides thermal insulation for applications where superior performance is needed.

BENEFITS OF SYNEFFEX™ THERMAL COATING

No Downtime- Apply Without Shutting Machinery Down

No Cladding Required Eliminating the Threat Of Hidden CUI

Can Be Applied To Nearly Any Surface

Meet OSHA Safety Standards

Long-Term Solution, 10+ Years

Be A Hero! Save Your Company Time & Money

No Corrosion