Reduced exterior temperature of their diffuser by 30C-35C / 54F-63F.

Problem

Illovo Sugar Limited is the largest listed sugar and alcohol manufacturer in Africa. They were looking for a solution for insulation of their Diffusers. They have had an ongoing initiative for energy efficiency and continue improving this in their mills.

Solution

Maxlife Coatings was approached to apply a test coating of 108 m² on one of their diffusers in order to insulate and minimize the energy loss through the walls of the diffuser.

Nansulate™ Translucent PT was chosen as the product of choice at Eston Sugar mill. During spring of 2013, the entire area was hand cleaned and pressure washed with Holdtight 102 to ensure the substrate was free from surface contaminants before coating application. A stripe coating with aluminum based Rust Bullet was applied to treat the surface.

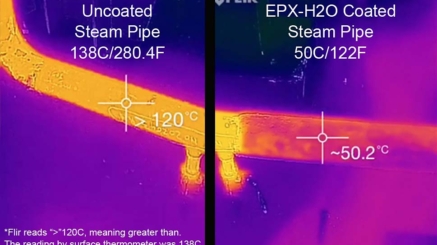

Nansulate™ Translucent PT was applied to belly and side walls of the diffuser. The original operation temperature of the diffuser ranges from 90C-80C (194F-176 F). After the application of 9 coats of PT and a full curing time of 90 days the temperature on the outer skin was reduced down to between 55C-50C (131F-122 F).

Project achievements – Temperature reduction of 30C-35C (54F-63F).

Standout Results!

The final analysis showed that Nansulate™ Translucent PT provided a cost effective and long term solution for insulating difficult to insulate equipment, reducing the exterior temperature by 30C-35C (54F-63F).