Syneffex™ Thermal Insulating Paints Testing Data

Energy Saving

Anti-Corrosion

Mold Resistant

The most reliable and trustworthy long-term solution to energy savings and surface protection on the market.

Outstanding Results in

Independent Laboratory Testing

& Field Studies

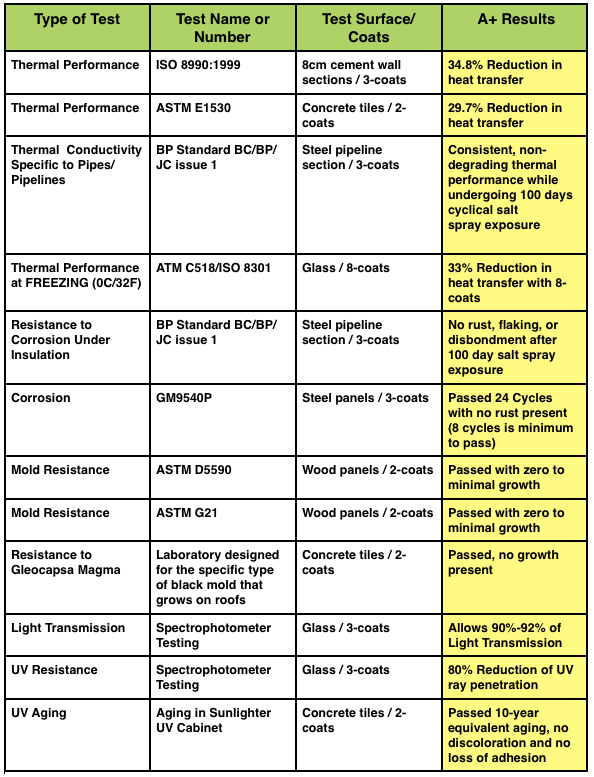

Extensive testing data by multiple independent laboratories and extensive field studies around the world confirm that Syneffex™ patented coatings are the best insulation for thermal protection, mold protection, and corrosion prevention in many industrial and building applications. We stand by our product, as do organizations around the globe that have experienced their sustainable benefits up close. The results speak for themselves.

Syneffex™ Thermal Testing Data

Thermal Testing Standards

- ISO 8990:1999 – Thermal Performance – Reduced heat conduction 34.8% (3-coats)

- ASTM E1530 – Thermal Resistance – Reduced heat conduction 29.7% (2-coats)

- BP Standard BC/BP/JC issue 1 – Thermal Conductivity – Consistent thermal performance while undergoing 100 days cyclical salt spray exposure

- ASTM C518/ISO8301 at FREEZING (0C/32F) – Thermal Conductivity – Heat transmission reduced 33% (8-coats)

Other Testing Standards

- BP Standard BC/BP/JC Issue 1 – Resistance to CUI – No rust or flaking after 100 day salt spray exposure

- GM9540P – Accelerated Corrosion Test – Passed 24 Cycles with no rust present

- ASTM B117 – Accelerated Corrosion Test (EPX) – Passed 750 hours

- ASTM D5590 & ASTM G21 – Mold Resistance – Passed with zero to minimal growth

- Resistance to Gleocapsa magma (black roof mold) – Passed, no growth present

Independent Testing Data

The test standards referenced below have been developed by the International Standards Organizations of ASTM and ISO, as well as other standard testing authorities, such as British Petroleum (BP) and General Motors (GM).

ASTM stands for the American Society for Testing and Materials and is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services.

ISO stands for International Organization for Standardization and is an international standard-setting body composed of representatives from various national standards organizations.

Thermal Paint by Syneffex™

Frequently Asked Questions

Can I test the thermal performance right away?

If you’re testing our Nansulate™ EPX-H2O, fast cure product, Yes. As soon as the coating film is completely cured, which is only a few hours if applying on a hot surface, or 1-2 days if applying to a non-heated surface.

For our other 1-part coatings…

The coatings are water-based, so just like paints, they have a cure time. If you plan to conduct your own studies of the thermal resistance or reduction of surface temperature, you must allow the coating to cure completely before full thermal abilities can be measured accurately. See our FAQ Page for more information on this as well as the proper thermometers to use (don’t use laser/infrared thermometers).

The typical cure time for an application of 3-coats at ambient temperature, medium humidity is approximately 30-days. High Humidity, higher film builds, and other environmental factors can increase the cure time. During the cure time the excess moisture (which conducts heat) is dissipating from the coating, and as this happens, the thermal performance of the coating is improving.

Do the coatings have an R-value?

This is common question, and to understand the answer, you need to understand where the R-value came from.

Our coatings, as well as other thin film insulators, do not have an R-value. This is because the R-value relies on a material’s thickness for at least 1/2 of the final number value, so attempting to use it for any material less than an inch will give an inaccurate result of the energy saving value of that material. It’s a case where the measurement standard has not progressed as fast as the technological innovations.

This is why we have used thermal testing that measures direct heat conduction in energy units (such as watts), that is not dependent upon thickness. These types of tests measure the ability to insulate and reduce thermal conductivity, no matter how thin or thick a material is.

Trust Syneffex™

Outstanding Real World Performance

Real world performance is just as important as how a technology tests in the lab. How else will you know if your laboratory results correlate with what your customers experience in every day life?

Here are a few field study references that show the exceptional energy saving & insulating performance of our coatings.

1) Residential Home Ceiling/Attic – Tulsa, Oklahoma:

2 1/2 years PRE-Syneffex™ Energy Protect™ coating were compared to 3 years POST-Syneffex™ Energy Protect™ coating.

Result: Average energy savings of 46% reduction of cooling costs.

2) Government Data Center – Monterrey, Mexico

A year-over-year comparison during the hottest month of the year was done inside the server room of their data center. Three coats of Syneffex™ Crystal roof coating were used to stop heat from the exterior from overheating the servers.

Result: 27% reduction in internal temperature.

3) Elasteks Textile – Turkey

A comparison of the steam consumption per yarn dyeing cycle was performed to gauge energy savings after Nansulate™ EPX-H2O was applied to insulate dyeing machines in their factory.

Result: A 51% reduction in energy consumption. Pre-coating steam consumption per cycle was 1,326kg, and after coating was only 651kg.

Syneffex™ Award Winning Energy Saving & Safe Touch Technology

For over a decade, Syneffex™ has helped companies become more sustainable and meet many of their corporate sustainability goals. We are proud to be the ones that corporations around the world come to when they need to solve a critical insulation or surface protection issue. We’ve served the needs of multiple industries globally, including oil and gas, pulp and paper manufacturing, food and beverage manufacturing, textile manufacturing, commercial and historical building owners and many others. Besides just thermal protection and corrosion prevention, our thermal insulating paint technology also offers several protective benefits such as mold/mildew resistance and UV resistance.

Our thermal insulating paints are designed to make any work environment better while providing energy saving benefits. We helped the Bangkok International Airport insulate airway bridges with a sustainable technology, and helped the U.S. Army and U.S. Navy insulate pipes to save energy and keep cold water cool and hot water hot.

Industries served include:

- Breweries and Distilleries

- Food and Beverage Manufacturing

- Pulp and Paper Manufacturing

- Textile Manufacturing

- Chemical Manufacturing

- Oil and Gas Production

- Plastic/Rubber Manufacturing

- Tire Manufacturing

- Military/Defense

- Consumer Products Manufacturers

- And many more!

Equipments served include:

- Chemical Processing Tanks

- Steam Pipes and Valves

- Food and Beverage Processing Tanks

- Textile Manufacturing Equipment

- Industrial Ovens & Ductwork

- Brewing Equipment

- Boilers

- Pulp and Paper Processing Equipment

- Pharmaceutical Processing Tanks

- Oil Pipelines, onshore and offshore

- Water Tanks and Lines

- Fryers

- Pasteurizer Tunnels

- And Many More!

Syneffex™ Insulating Paint Solutions

Effective Insulation and Surface Protection…

Everywhere!

INDUSTRIAL USE: Nansulate™ EPX–H2O is our #1 high temperature industrial corrosion protective and insulation paint. It is proven to solve the most difficult energy efficiency, corrosion, CUI, and safe touch problems of factories and all processing industries. Using Syneffex™ technology as insulation gives you peace of mind for 10-years or more knowing your application will be insulated and protected from corrosion and weathering. This next generation thermal insulation has you covered for all types of directives – energy savings, safe touch for employee safety, heat radiation reduction, and asset protection from chemicals and corrosion.

BUILDING USE: Energy Protect™ is a multipurpose, space-saving clear insulating paint for multiple building surfaces. It is the top product to increase energy efficiency in older buildings as a retrofit insulation. It works in all seasons, keeping your building warmer in the winter to reduce heating costs and keeping it cooler in the summer to reduce cooling costs. It also provides other powerful protective qualities, such as UV resistance, mold and moisture resistance, and corrosion prevention, all in one powerful and clear thermal paint.

This Factory saved $460,000/year in Energy Costs

SOLID ENERGY SAVING RESULTS!

Textile manufacturer Henateks, who makes apparel for Nike, Adidas, and Tommy Hilfiger, insulated their boiler, dyeing machines and steam pipes with Syneffex™ coatings.

Project Cost: $200,000

Annual Savings: $460,000

This factory saved $18,000/year in Energy Costs

PAYBACK IN JUST 5 MONTHS!

With over 30% savings on energy costs from insulating their heat process equipment, this manufacturer was thrilled to get a payback from insulating with Syneffex™ Coatings in just 5 months.

Project Cost: $7,500

Annual Savings: $18,000

Note: Referenced tests were conducted by accredited 3rd party laboratories to internationally recognized testing protocols and standards. We do not provide input or feedback on self-designed test models, but rather rely on the international standards and other protocols designed by experts in the field.

Sustainability Simplifed™

Be Brilliant. Buy Now.

✅ Easy Application

✅ Safe Touch Solutions

✅ Increased Asset Lifespan

✅ Mold and Mildew Resistant

✅ Corrosion and CUI Resistance

✅ Resistant to UV and Color Fade

✅ Protects From Sea Spray and Salt Air

✅ Thermal Insulation and Energy Savings

✅ Reduce Carbon Footprint and Green House Gases (GHG)