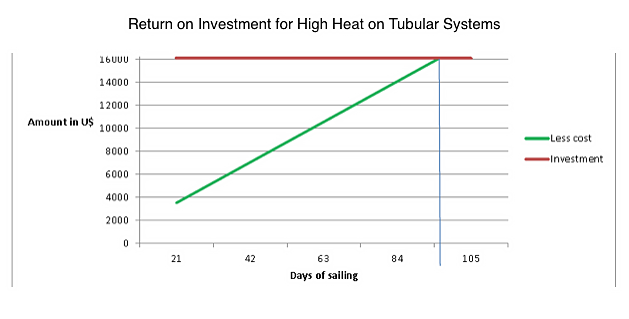

Diesel fuel use reduced by 360 liters per 24 hours – Payback achieved in only 95 days of sailing.

Problem

Lower fuel costs and carbon emissions for container vessel while also providing corrosion resistant insulation for the heavy fuel oil (HFO) system.

Fuel is a significant operating cost of any container carrier or other maritime vessel, so changes in fuel costs can dramatically impact a company’s bottom line. According to TSACarriers.org, “Fuel accounts for 60 percent or more of total voyage operating costs for a typical scheduled container service.”

Solution

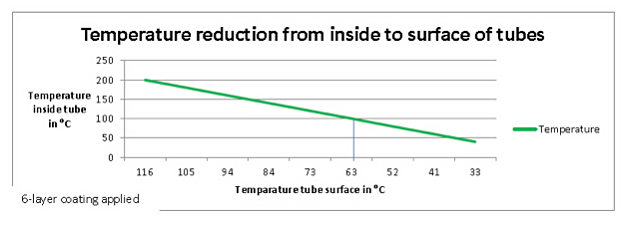

European marine services company, NTA Maritime, saw the potential to significantly lower these fuel costs using our Nansulate™ High Heat thermal insulation coating, and they succeeded in reducing diesel fuel use by thirty percent. Nansulate™ High Heat coating was applied to the tubular system and tanks of the HFO system for insulation and to prevent corrosion under insulation. The Nansulate™ High Heat was overcoated with a marine top coat to protect it from salt water. The coating reduced the diesel fuel used to heat the HFO system by 30%, reducing the daily diesel fuel use by 360 liters per 24 hours, which equates to more than 7,500 liters of diesel fuel saved during a typical 21 day round trip Asia/US/Asia journey, equivalent to approximately $3,525 USD or more in cost savings. The project was undertaken on a 3,725 TEU container vessel owned by Yang Ming Marine. The Nansulate™ High Heat insulating and anti-corrosion coating was applied to the HFO tanks and tubular system at a coverage of 6-coats, totaling a 200 micron dry film thickness. The cost of application and materials used to insulate the HFO tanks and tubular systems was $16,100 USD. The return on investment was achieved after 95 days of sailing. Reduction of Carbon Emissions: If we use the well-to-wheel emissions factor for diesel oil of 2.9kg CO2/liter, that is a savings each 24 hours of sailing of 1,044kg of CO2 emissions. For a 21 day voyage, that’s a reduction for one vessel of 21,924kg (24 tons) of emissions.

Slowed down heat flux from HFO tanks to wing and double-bottom tanks

Prevented corrosion under insulation (CUI)

Cost for product and application was $16,100 USD

Payback achieved after just 95 days of sailing.

Standout Results!

The final analysis showed that Nansulate™ High Heat provided an excellent, durable, and anti-corrosive insulation for the tanks and tubular system of the heavy fuel oil (HFO) system. A 6-coat coverage lowered fuel costs by 30%, which equates to a reduction of more than 7,500 liters of diesel fuel and 24 tons of carbon emissions for a typical 21 day voyage.