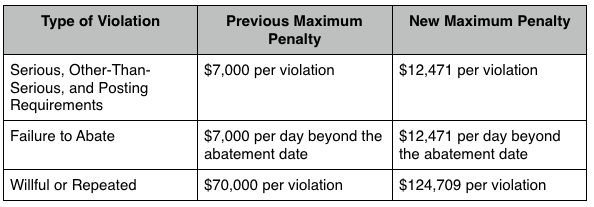

If you’re in the United States, then you know the importance of compliance with OSHA (Occupational Safety & Health Administration). They regulate multiple types of employee safety guidelines and fine companies when they find a compliance violation. As of August 2, 2016 new penalties have taken effect for any citation issued by OSHA on and after that date if the related violations occurred after November 2, 2015. (https://www.osha.gov/penalties/)

The penalty increases mean that organizations are reviewing any areas where safety compliance may be an issue, such as keeping all surfaces to a safe-to-touch level to prevent employee burns. This is a safety related area that we help companies with every day by recommending one of our thermal insulation coatings for a hot surface like a boiler end cap, steam pipe, oven, or other types of heat process equipment. An added benefit, of course, is the energy cost savings from reducing heat loss from the equipment.

The new OSHA penalties now in effect represent

an increase of 78.2% in maximum fines:

Some of the pertinent OSHA regulations dealing with heat related worker injuries are:

1910.261(k)(11):

Steam and hot-water pipes. All exposed steam and hot-water pipes within 7 feet of the floor or working platform or within 15 inches measured horizontally from stairways, ramps, or fixed ladders shall be covered with an insulating material, or guarded in such manner as to prevent contact.

1910.262(c)(9):

Steam pipes. All pipes carrying steam or hot water for process or servicing machinery, when exposed to contact and located within seven feet of the floor or working platform shall be covered with a heat-insulating material, or otherwise properly guarded.

Section 5(a)(1) of the OSHAct:

Each employer shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his employees.

How Syneffex™ insulation coatings can help prevent worker injuries

Our Nansulate™ line of industrial insulation and corrosion prevention coatings is meant to do just that, provide a shield from the heat. Our EPX-H20 is the most powerful, and is used daily by companies around the world to lower hot surfaces at 170F and above to an employee safe touch range easily.

Both our Nansulate™ EPX-H20 and Nansulate™ High Heat can significantly increase safety in two important ways:

- Reduce hot surfaces to a safe touch level.

- Reduce heat radiated into the working environment to reduce employee heat stress and heat stroke risk.

Long lasting means no nasty surprises.

Because our coatings are long lasting, 5-10 years or more, and do not break down and degrade like fiberglass or mineral wool, you won’t get any nasty surprises that can happen with traditional fibrous insulation that can break down and allow surfaces to get into the burn range without you realizing it. Our technology is designed to insulate at the same level throughout its lifetime, so you know that once you have it in place you don’t have to worry about consistent performance and temperature.

Which Nansulate™ product should we use

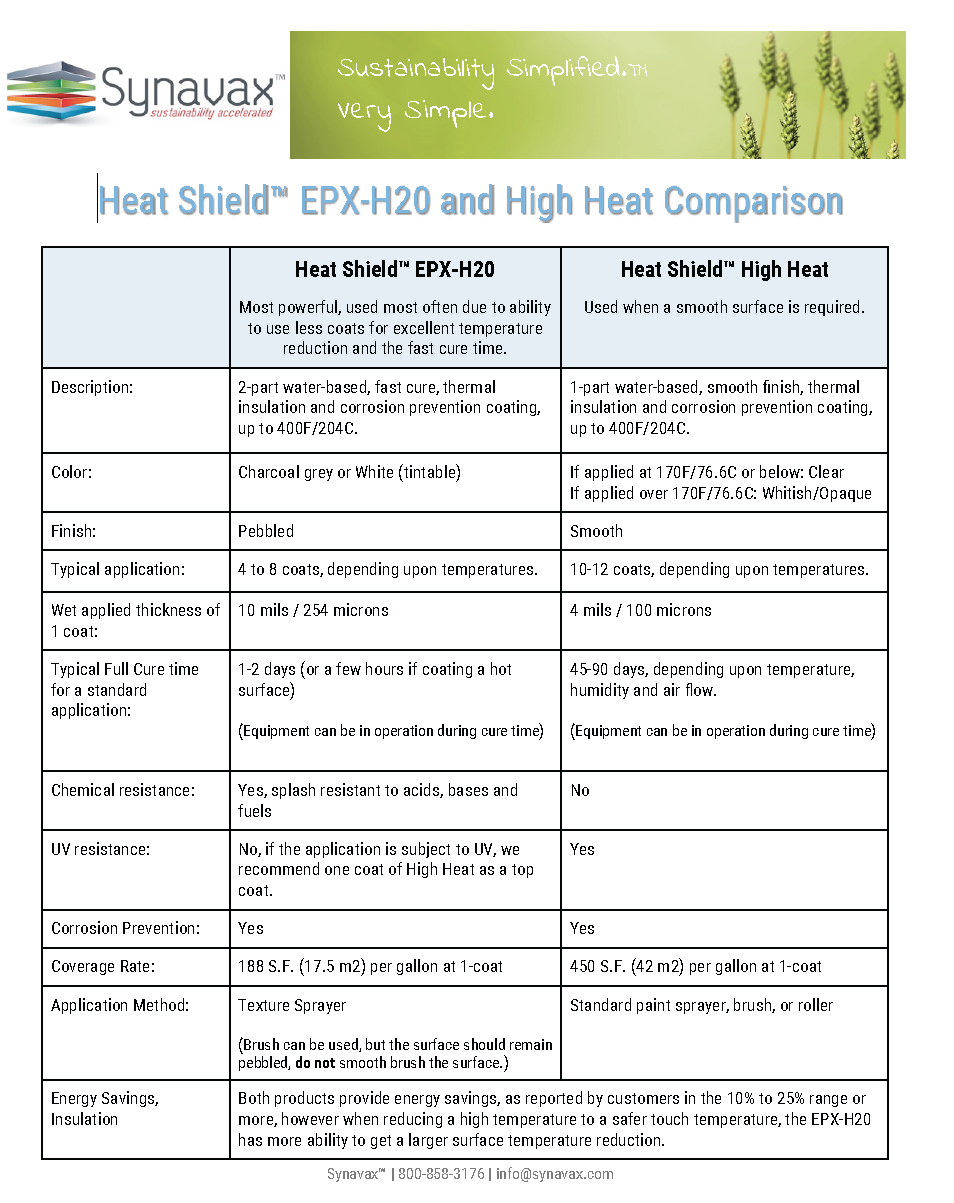

We get this question often and have created a helpful side by side chart comparing both the EPX-H20 and High Heat coating so you can see which will best meet your safety and energy saving needs.

Check out each product on our website here for pricing and other product downloads:

Nansulate™ EPX-H20: www.syneffex.com/product/heat-shield-epxh2o-thermal-insulation-protective-coating

Nansulate™ EPX-H20 Premiere Kit (with Sprayer): www.syneffex.com/product/heat-shield-epxh2o-premiere-kit

Nansulate™ High Heat: www.syneffex.com/product/high-heat

Lastly, our customers love that they can apply our products themselves or use a contractor and there is no delay in installing a safe touch solution to reduce employee injury risk. Our coatings can be sprayed on while your equipment is in service and the EPX-H20 cures right away, within a few hours to 1-2 days. We pride ourselves on Sustainability Accelerated™.

With OSHA fines increased over 78%, it stands to reason that there might be an increase in oversight to accompany the significant boost in fines. If you have potential safety hazards related to burn risks, we can help you deploy a quick, effective, and long lasting solution. Order today, apply the coatings to your in-service equipment, and check this off your list next.