Did you know?

21 Countries are significantly reducing their carbon emissions while growing their GDP at the same time. (Source: World Resource Institute).

Insulating heat process equipment is the simplest, easiest, and fastest way industries can increase profits and reduce energy consumption and related greenhouse gas (GHG) emissions.

While there are many different ways to both increase profitability for your company and lower your carbon footprint to help reduce your global impact, using Syneffex™ nanocoating technology, which has a lifespan of 5-10 years or more, to insulate is one of the easiest, simplest and most productive ways to do both at the same time.

Using insulation that only lasts a couple of years, especially in manufacturing facilities, is a waste of time, energy and money. But using an advanced thermal barrier insulation coating that is proven effective for a decade or more… now that’s smart.

Smart for your company, smart for your facility, and smart for the planet.

Let’s take a closer look at exactly how Syneffex™ thermal insulating and corrosion prevention coatings actually save you more in the long-run when insulating pipes, tanks and other surfaces.

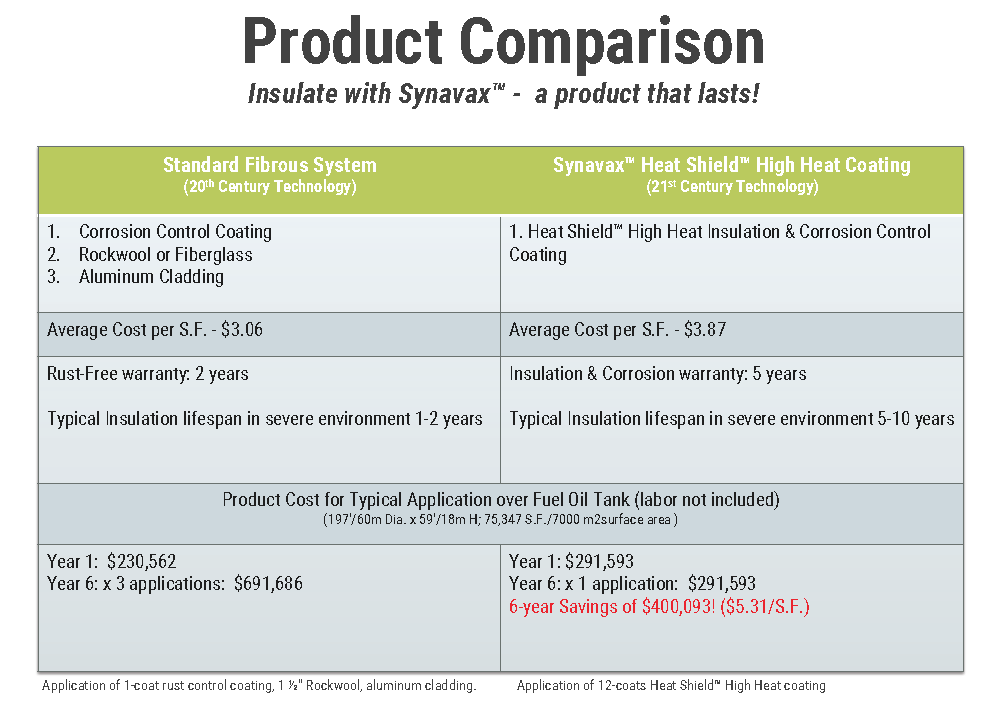

Insulation Comparison Chart

The comparison chart below is based upon the performance achieved by one of the largest oil and gas companies in the world. They found that just 12-coats of our High Heat coating not only insulated within 3 degrees of 8 centimeters of mineral wool and aluminum cladding (jacketing), it also saved them more money (not reflected in the chart) by preventing corrosion and protecting their tank assets from degradation. This is a great illustration of how the long-term durability and consistent moisture resistant qualities of our products save money and increase profits.

What Energy Savings Means to Reducing Carbon Emissions

Here is another example of how energy savings relates to lowering carbon emissions:

The Nansulate™ High Heat insulation coating was used at a hospital for steam pipe insulation. The application used an 8-coat coverage, which is approximately 8/1000’ths of an inch thickness and provided approximately a 110F (61C) temperature reduction, lowering the surface temperature from 302F (150C) to 192F (88.9C) degrees and reducing the amount of fuel needed to create the same amount of work. Quite an accomplishment for a thin film coating, but that’s the magic of nanoscience and our next generation insulation coatings.

What This Meant for the Planet

Using the temperature reduction details and BTU savings from the case study above, for every 1,000 S.F. of steam pipe surface area insulated with Syneffex™ coatings:

- Annual savings of 3,046.20 MMBtu/year

- Based on today’s energy dollars, that’s $8,285.66 USD/year savings on liquid natural gas

- Savings of 162 Metric Tons of GHG emissions, according to the U.S. EPA’s GHG emissions equivalency calculator

Saving Energy Means Increasing Profits and Protecting the Future

Whether climate change is a priority for your organization or you’re focused more on the bottom line… or both… there are duel benefits you get from using Syneffex™ coating technology that both increase your profitability from saving on energy and lowering maintenance costs AND reducing energy related carbon emissions.

Either way, don’t wait, insulate!

We suggest you start with our fastest cure industrial coating, Nansulate™ EPX-H2O to get the most power and best performance available.

Not sure where to start? Just use our request form or chat below to request a recommendation. We will get one to you in 24-48 hours.