In this week’s CSR Series, we are going to touch on something that is applicable to both industrial and building insulation and energy saving projects. A major consideration when evaluating sustainable technology is the installation or application cost, not just the material cost.

When installing some types of energy efficiency technologies, the labor cost to install can be a big chunk of the total project expense. For example, according to homewyse.com the typical labor cost for installation of Rockwool insulation can be more than 50% of the total project cost.

And when it comes to fiberglass and cladding, or aluminum jacketing, costs to install the cladding, banding, and screws over the fibrous material not only mean high labor cost but also downtime during the installation process. Downtime can cost factories hundreds of thousands of dollars a day in lost production time.

This is another important reason that Syneffex™ thermal insulation coatings are becoming the main technology that factories look to first for insulating tanks, pipes, and other equipment. They are easily installed with a standard paint or texture sprayer and can be applied in most cases while the equipment is in service. The application is also easy enough for an organization’s own maintenance crew to do.

Easy application is one of the factors in our exceptionally short payback periods both for equipment and building insulation projects. Industrial customers report 6-18 months payback and building customers report 3-5 years payback. Both of those are much shorter than the standard payback of other factory or building energy efficiency technologies.

Of course, other benefits are that they prevent corrosion instead of causing it, like other insulations do, and the moisture resistance and 10 year+ longevity with consistent insulating performance throughout their lifespan.

How Easy Are Syneffex™ Insulating Paints To Apply?

When we say “as easy as painting” we mean it. All of our insulating coatings can be sprayed on easily, with some also having the ability to be brushed or rolled. There is no cladding to affix and screw into place, which greatly reduces the labor cost and time to install.

The film thickness can easily be checked with a wet film thickness gauge while applying (see PT video below), or a dry film thickness gauge after the film is completely dry.

Recommended Equipment Needed

You don’t have to buy expensive equipment to apply our products and in many cases a contractor or your maintenance manager will already have what they need.

For those wanting a few suggestions on typical equipment that you can use, here are a few links below that take you directly to the Amazon page for each:

Application of Nansulate™ EPX-H2O – This product is a little thicker than our other coatings, so you’ll use a texture sprayer for application.

Wagner 0520000 Power Tex Texture Sprayer

Graco 17H572 TexSpray RTX 1400SI Texture Sprayer

Application of all our 1-part coatings, both the industrial and building coatings.

You can use standard paint sprayers to apply. Here are a few of our contractors’ favorites:

Graco 257025 Project Painter Plus Paint Sprayer

Graco 17G180 Magnum ProX19 HiBoy Paint Sprayer

Wagner 0529010 Flexio 590 Indoor/Outdoor Hand-held Sprayer Kit

Titan Impact 440 High Rider Airless Sprayer 805-016 with Free Spray Pack

Ancillary Items

Here are some other items that will make application go smoothly.

ABN Paint Mixer for 1-5 Gallon Buckets

BYK-Gardner 5629 PosiTector 6000 Dry Film Gauge, Ferrous Substrates

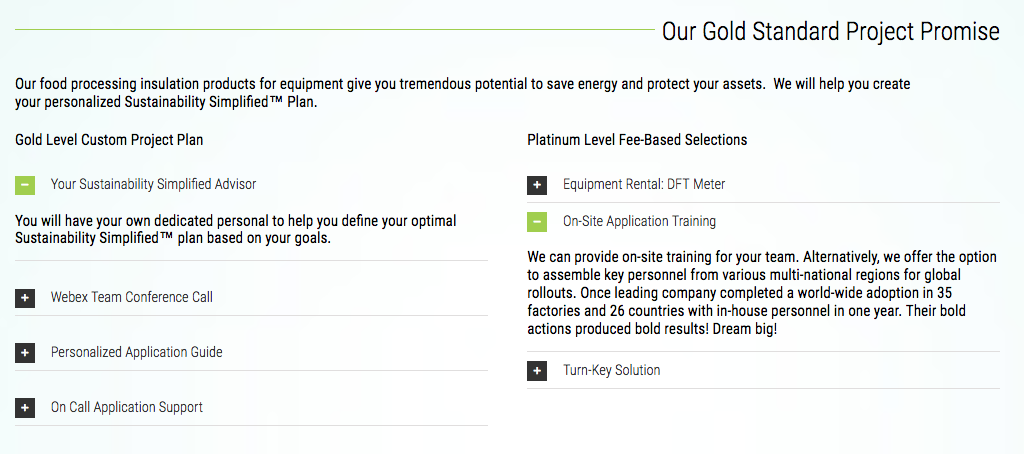

You Have Your Own Technical Team With Our Gold Standard Application Support

We know that a proper installation is vital to the success of any project. We are there with you every step of the way with personalized, complimentary webinar training, technical documentation, and technical support available by email, phone, and video call before and during your day of application.

Summing Up Why Easy Application Means Faster Payback

There are a number of reasons you’ll get a faster payback on your entire project with Syneffex™ easy application coatings:

- No downtime for factory

- Shorter installation time

- No cladding, banding, or screws to buy

- Prevents corrosion, less maintenance costs

- No expensive equipment to purchase

- Application can be done by painting contractor or your own maintenance crew

- Outstanding Gold Standard Support is complimentary

Would you like a 20-30 minute installation overview? Just contact us today and we’ll get that scheduled and show you just what we mean by “Easy Application” and Sustainability Simplified™!