When it comes to choosing the best insulation for your facility, the proof is always in the performance. That’s one of the reasons that we always tell people to try it for themselves if they’re feeling unsure, because we know that our thermal insulation coatings speak for themselves.

You can do energy saving calculations and estimates, but when push comes to shove, energy and facility managers just want to know the insulation for their pipes, tanks, and other equipment is going to lower surfaces for safe touch applications and reduce their energy costs.

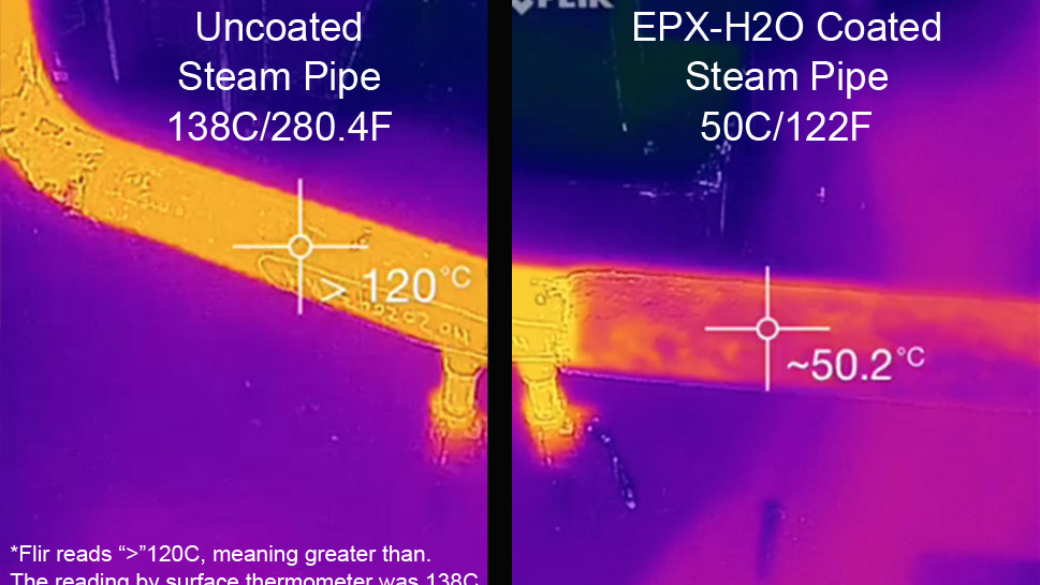

So, you’ll definitely want to check out the latest field application shared with us from our South African based Distributor, Syna-Africa. The Flir video speaks volumes about the performance you’ll see from our powerful and patented thermal insulation coatings.

Background Details:

Client: Large Paper Mill

Surface: Steam Pipe

Product: Nansulate™ EPX-H2O

Number of Coats: 6

Total applied thickness: 1.5 mm (0.25 mm per coat)

Cure time after application: 24 hours

Uncoated Temperature: 138C (280.4F)

EPX-H2O Insulated Temperature: 50C (122F)

Temperature Reduction: -88C (-158.4F)

Temperature reduced to safe touch in just 24 hours!

Watch the video below of the Flir thermal imaging.

What does this mean for you?

It means you can easily spray on a thermal insulation coating that will last for 10 years or more. No more corrosion under insulation worries, no more need to put on exterior jacketing, and no more insulation that degrades in just a year or two due to moisture or dirt.

If you’ve been skeptical of Syneffex™ thermal insulation coatings in the past because you’ve thought they were “too good to be true,” we say… Try them, and they will prove it to you!