We’re excited to share a new case study that is in from our Distributors in South Africa. They provided some excellent Flir thermal imaging photos and their application not only showed the power of the Nansulate™ EPX-H2O coating to quickly lower a hot surface to a safe-to-touch level for safety, it also shows how the insulation “fits like a glove” over non-flat and irregular surfaces.

It’s perfect timing, as I also just returned from overseeing a boiler insulation project for a large residential apartment building in New York. I’ve shared below a few photos that beautifully illustrate how easily the EPX-H2O coating fits over all equipment surfaces to seal the thermal envelope and give you the best energy savings possible.

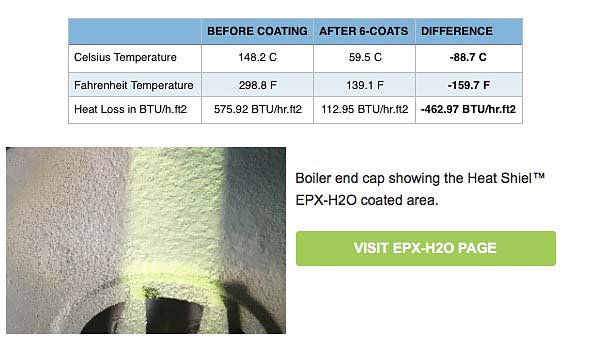

Boiler Insulation | Temperature Reduced by -88.7C (-159.7F)

During a recent thermal insulation trial on a boiler, our Distributor in South Africa illustrated the power of the Nansulate™ EPX-H20 for an industrial energy management company.

The application was performed on a section of the boiler that was 148.2 C (298.8F) and the goal was to bring the surface to a safe-to-touch level. After a 6-coat application, the coating reduced the surface temperature to 59.5C (139.1F), more than reaching the goal to safe touch and also illustrating the insulating and energy saving benefits of the coating, as well as the ease of application to both flat and non-flat surfaces.

Easy to Spray On and Fits Like a Glove!

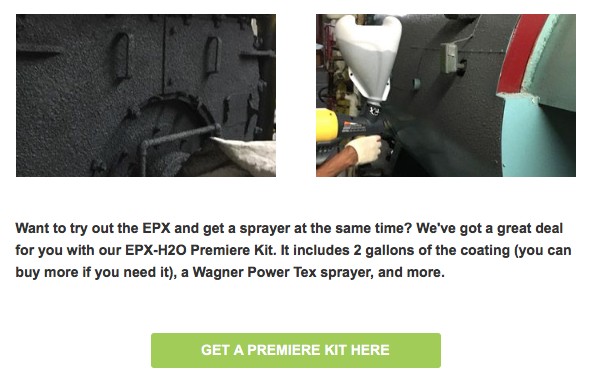

The Wagner Power Tex texture sprayer makes it very easy to spray apply the coating to a boiler, tank, steam pipe, or other equipment. A bonus is that you also seal up all those thermal leaks over non-flat areas that are almost impossible to insulate with anything else.

Here are a few photos from that NY application I mentioned that show you just what I mean. (PS: The application only took about half a day.)