Boilers, which are the heart of the heat generating process, are a key piece of equipment in factories, hospitals, universities, institutions, and many medium and large buildings. Unfortunately, they can be a challenge to insulate with fiberglass or mineral wool for a number of reasons, including that the size of the boiler doesn’t make it easy to wrap and cover, fibrous insulations cause corrosion issues, and it’s not always possible to take the boiler offline for work to be done.

Conductive and Radiant Heat Loss

Heat emanates from boilers during operation, not only causing energy costs to go up, but also creating hot conditions in the room where they are located. Boilers are also notorious for being “hot areas” for employee burn risk.

Our CEO recently visited a factory where hot boiler surfaces were an employee safety issue.

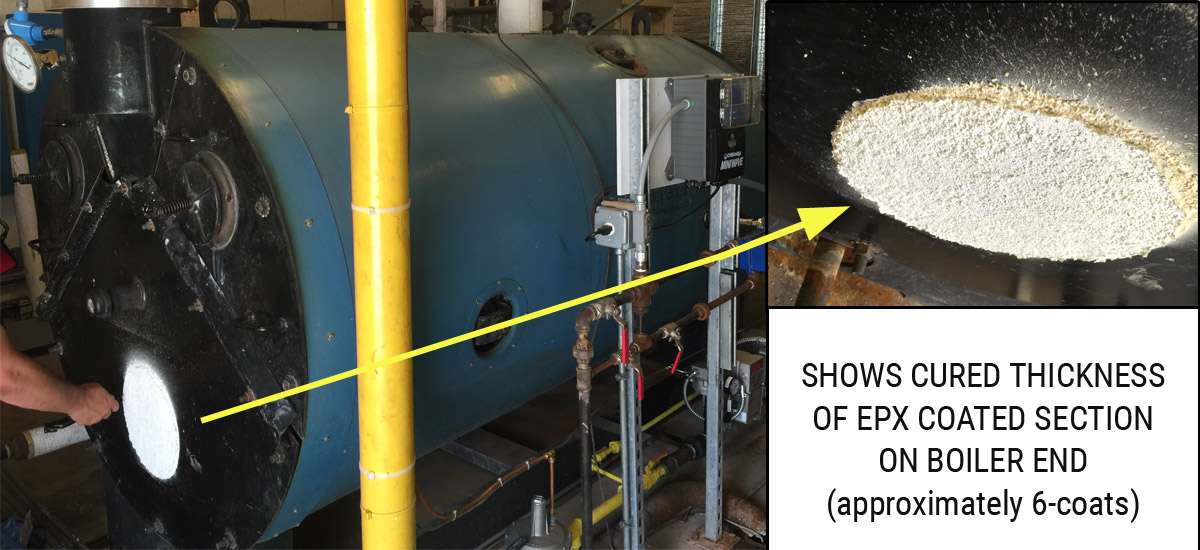

Their boiler was at approximately 275F and they needed a safe touch solution right away. We sprayed on several coats of our EPX-H20 coating, and by the end of that same day, they were able to safely touch the boiler with no issues. The coating cures quickly, in approximately 1-2 hours, when applied to a hot surface, it is dry to touch. It was sprayed on while the boiler was in-service, so there is no downtime.

Powerful Boiler Insulation

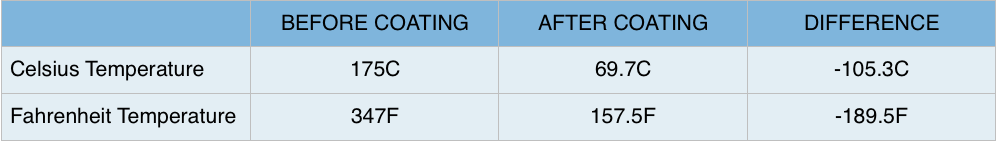

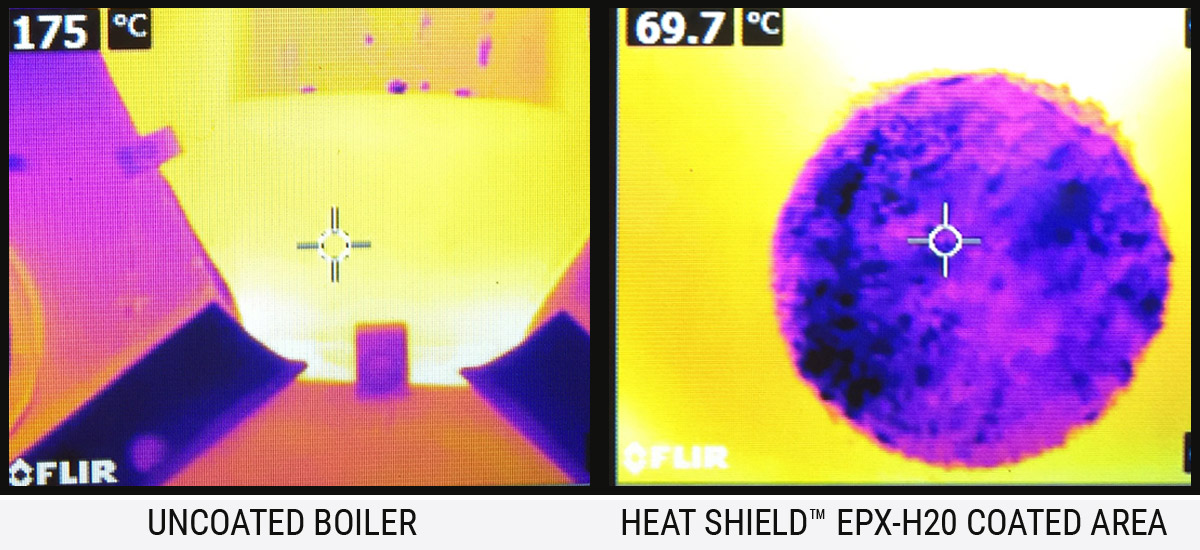

During a recent boiler trial at a large paper mill, we showed the plant manager just how powerful our technology works. Even through heat was radiating around the small test patch where our EPX-H20 coating was applied on the end caps, which of course reduces the overall results, the thermal images below show that our coating resulted in a clear and substantial difference.

Syneffex™ Nansulate™ EPX-H20 is an easy All-in-One thermal insulation coating that can be easily spray applied to boilers to provide both insulation and corrosion and CUI prevention. It does not require the equipment to be taken offline, you can spray while the surface is hot and feel it get cooler with every coat. It dries to the touch in approximately 1-4 hours, depending upon surface temperature.

The main boiler solutions that our patented coating technology provides are:

- Surface temperature reduction to safe touch

- Energy saving insulation

- Reduction of heat loss from the boiler

- Reduction of heat radiating into the working environment

- Fast cure – in just a few hours to a day

Henateks Energy Savings Average 20%

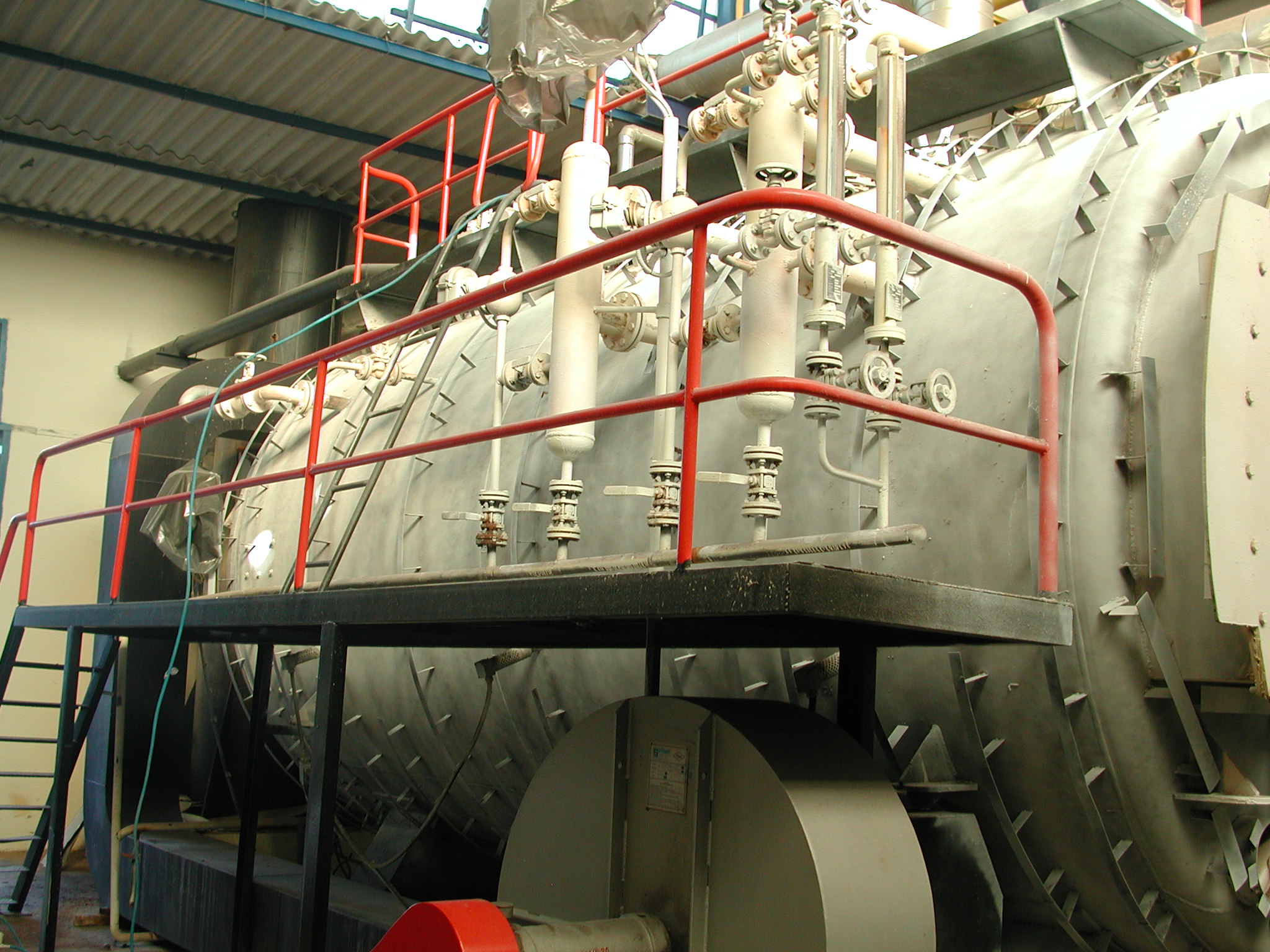

Henateks is a textile manufacturer for Nike, Adidas, Tommy Hilfiger and other well-known US clothing brands. They discovered Syneffex™ insulation technology many years ago and used it to coat their boilers, steam pipes, and textile dyeing machines. Their project payback was in just 7 months, annual savings averaged 1 million cubic meters of liquid natural gas, which at the time of their reporting in 2006-2008, equated to approximately $460,000 USD per year.

So, if you’re looking for an easy project you can do in a day that will make a significant positive impact on your corporate sustainability goals for energy savings and employee safety and help you reach an OSHA safe touch, you’ll definitely want to try our Nansulate™ EPX-H20 insulation coating. You can even purchase the sprayer along with it in our EPX-H20 Premiere Kit.

How Do I Insulate My Boiler?

- Contact us with the boiler diameter, length, and surface temperature.

- We’ll send you a specification for the recommended number of coats and a quote for the product needed.

- Once you order, we send easy application instructions right in the box, and you can also call us anytime for free technical assistance.

- Spray on the coating using a texture sprayer. A typical application can be done in just a day.

Or if you want to do it all yourself, you can estimate for a 6-coat application, 31.33 S.F. per gallon ( 2.92 m2 per gallon), and order online here: www.synavax.com/product/heat-shield-epxh2o-thermal-insulation-protective-coating