When a denim manufacturing company contacted energy efficiency expert, Kolorgen Ltd., they had an interesting challenge. They’d never been able to insulate their rotating drying cans to save energy. This was due to the limited amount of space and the constant rotation during the manufacturing process.

Fiberglass, mineral wool, foam… nothing they found was suitable. That is, until Kolorgen introduced them to Syneffex™ patented thin film thermal insulation technology.

Their steam temperature was 160C (320F) and they were losing a lot of heat energy! The denim factory used Nansulate™ High Heat thermal insulation coating by Syneffex™ in an easy spray-on application that did not interfere with the rotation of the drying can array.

They were thrilled with the savings and grateful to have finally found a solution for energy savings on this equipment.

Bold Plans. Bold Results.

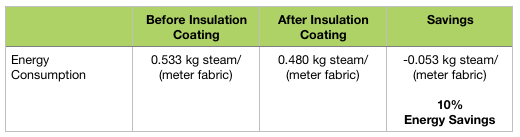

The results speak for themselves. This manufacturing client achieved:

Overall Energy Savings of 10%

Nansulate™ High Heat is a powerful thin film coating that is perfect for any tight spots that you want to insulate, but have limited space.